Cơ sở vật chất

Sản xuất ống thép

| Pipe OD (mm) | Pipe WT (mm) | Speed (M/Min) | Made in | ||||

| Min | Max | Min | Max | ||||

| 1 | No.1 ERW mill | 19.1 | 63.5 | 1.0 | 4.5 | Max 100 | Japan |

| 2 | No.2 ERW mill | 12.7 | 38.1 | Min | Max | Max 120 | Japan |

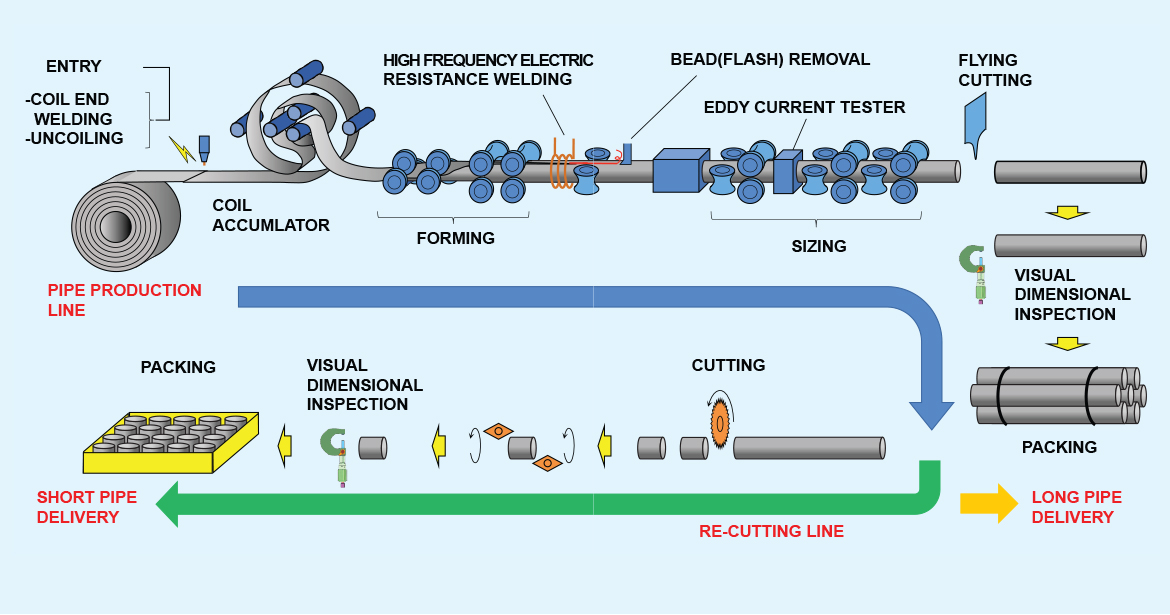

RECUTTING (METHOD: SAW BLADE CUTTING)

| 1 | Short Cutting | 11 auto and 02 manual machines |

| 2 | Brushing | 08 machines |

| 3 | Pressing | 03 machines |

| 4 | Polishing | 03 machines |

| 5 | Buffing | 04 machines |

| 6 | Facing | 06 auto and 02 manual machines |

Pipe QUALITY INSPECTING FACILITIES

| 1 | Eddy Current Tester (ECT) | No.1 ERW mill | Search coil (Encircling) type & Probe type |

| No.2 ERW mill | |||

| Offline | Search coil (Encircling) type | ||

| 4 | Tensile Tester | ||

| 5 | Flattening & Flaring Equipment | ||

| 6 | Micro Photo Equipment | ||

Quy trình sản xuất

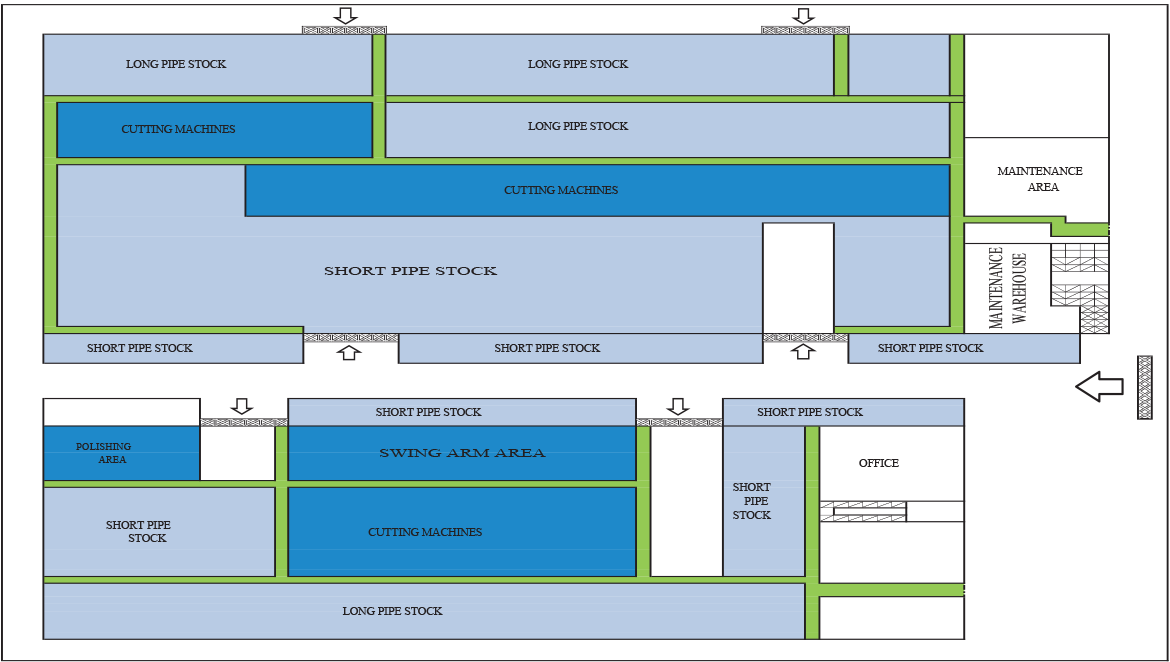

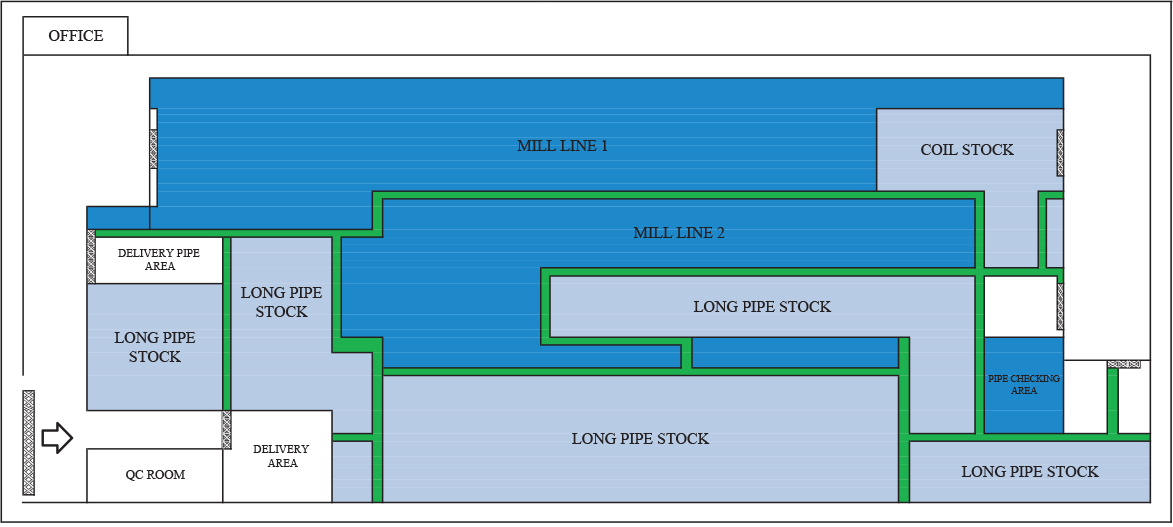

Cấu trúc nhà máy

FACTORY NO.1

FACTORY NO.2 & 3